主な製品

20年にわたる業界経験 |世界的に信頼される環境エンジニアリングソリューション

1.Superior Interface Stability Through Advanced Surface Texturing

2.Enhanced Chemical Resistance for Demanding Environments

3.Exceptional Durability and Long-Term Performance

4.Optimized Installation Efficiency and Seam Reliability

5.Proven Cost-Efficiency Through Lifecycle Value

In the realm of containment solutions, technical specifications alone cannot guarantee project success. As leading HDPE Geomembrane Manufacturers, we bridge the gap between theoretical performance and practical application through scientifically engineered products that address real-world geotechnical challenges.

|  |  |

1. Technical Evolution in Geomembrane Design

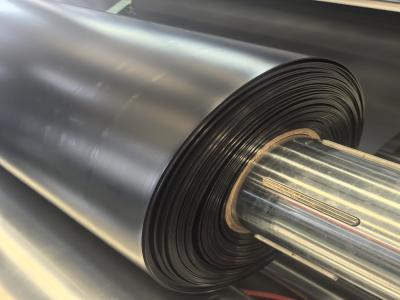

The fundamental purpose of any geomembrane—to provide reliable fluid containment—has remained constant, but the engineering behind these materials has undergone significant transformation. Modern HDPE Liner Manufacturers must consider complex interfacial relationships that go beyond basic impermeability. Our development of advanced texturing technologies represents a crucial innovation in this field. The proprietary manufacturing process at our Nitrogen spray Double Rough HDPE Geomembrane Liner China Factory creates a meticulously engineered surface topography that delivers superior interface shear strength compared to conventionally textured membranes.

2. Performance Characteristics Through Advanced Manufacturing

The distinction between adequate and exceptional geomembranes becomes apparent during installation and throughout the product's service life. Our focus on precision manufacturing yields several critical advantages:

1.Optimized surface texture creates effective mechanical interaction with various geosynthetics and soils

2.Enhanced material composition ensures consistent performance across environmental stresses

3.Superior stress distribution capabilities reduce localized strain concentrations

These characteristics make our HDPE Double Rough Surface Geomembrane 1.0mm particularly valuable in applications where interface stability cannot be compromised.

3. Documented Advantages in Complex Applications

Independent laboratory testing and field verification have consistently demonstrated the performance benefits of our manufacturing approach. The engineered surface of our geomembranes provides quantifiable advantages:

1.Interface friction angles increased by 25-40% compared to standard textured surfaces

2.Reduced installation challenges on steep slopes and challenging subgrades

3.Improved long-term stability through enhanced soil-structure interaction

These measurable benefits position our products favorably among those offered by other HDPE Geomembrane Suppliers.

4. Comprehensive Technical Parameters

While standard specifications provide necessary baseline information, meaningful quality assessment requires understanding parameter relationships. Our manufacturing process ensures consistent performance through:

1.Tight thickness tolerances across the entire membrane width

2.Homogeneous carbon black distribution for optimal UV resistance

3.Balanced physical properties that maintain integrity under various stress conditions

This technical consistency distinguishes products from reputable Geomembrane Liner Companies.

5. Diverse Application Methodologies

The versatility of high-quality HDPE geomembranes enables their use across multiple sectors:

1.Environmental containment systems requiring chemical resistance

2.Water management applications demanding long-term durability

3.Mining operations needing robust mechanical properties

4.Agricultural projects requiring reliable fluid retention

Each application benefits from the specific characteristics developed through our advanced manufacturing processes, including those from our Nitrogen spray Double Rough HDPE Geomembrane Liner China Factory.

6. Strategic Logistics and Quality Preservation

Maintaining product integrity during transportation and storage represents a critical phase in the quality chain. Our comprehensive approach includes:

1.Structural packaging systems designed to prevent core deformation

2.Climate-appropriate wrapping materials selected for specific destination conditions

3.Loading methodologies that minimize transit-related stresses

These protocols ensure that materials arrive on-site in optimal condition, ready for installation.

7. Technical Capabilities and Manufacturing Excellence

Our position among respected HDPE Geomembrane Manufacturers derives from continuous investment in both manufacturing technology and quality assurance. The integration of advanced production equipment with rigorous testing protocols enables:

1.Precise control over texturing parameters and material consistency

2.Comprehensive quality verification at multiple production stages

3.Technical support based on extensive material science expertise

This engineering-focused approach to manufacturing ensures that clients receive products that meet both specification requirements and performance expectations.

Conclusion: Technical Partnership Approach

Selecting appropriate containment materials requires careful consideration of both documented specifications and demonstrated performance characteristics. As experienced HDPE Geomembrane Suppliers, we provide comprehensive technical data and application support to facilitate informed material selection. Our engineering team remains available to discuss specific project requirements and demonstrate how our HDPE Double Rough Surface Geomembrane products can contribute to successful, durable containment solutions.